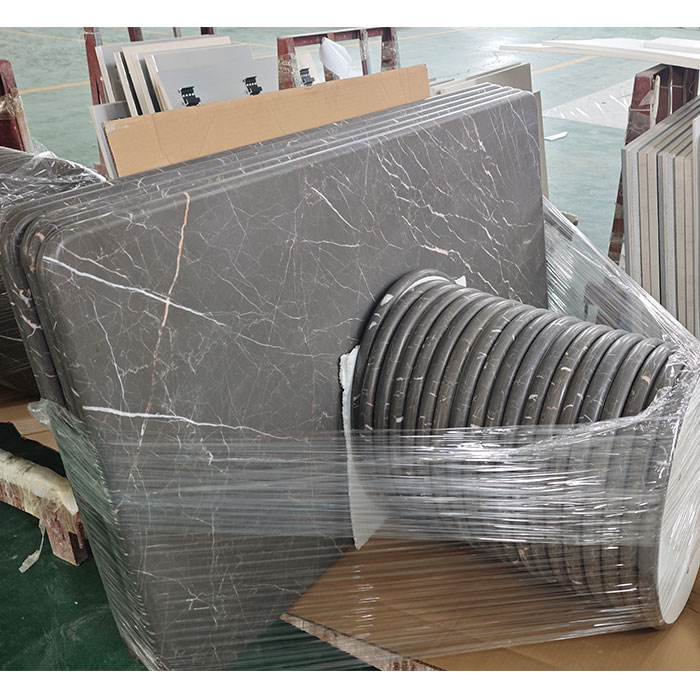

honeycomb panels for rvs and marine table top

- Huarui

- Foshan,Guangdong

- 10-25days

● Laminate Honeycomb Panel: The Ultimate Solution for RV and Marine Table Tops

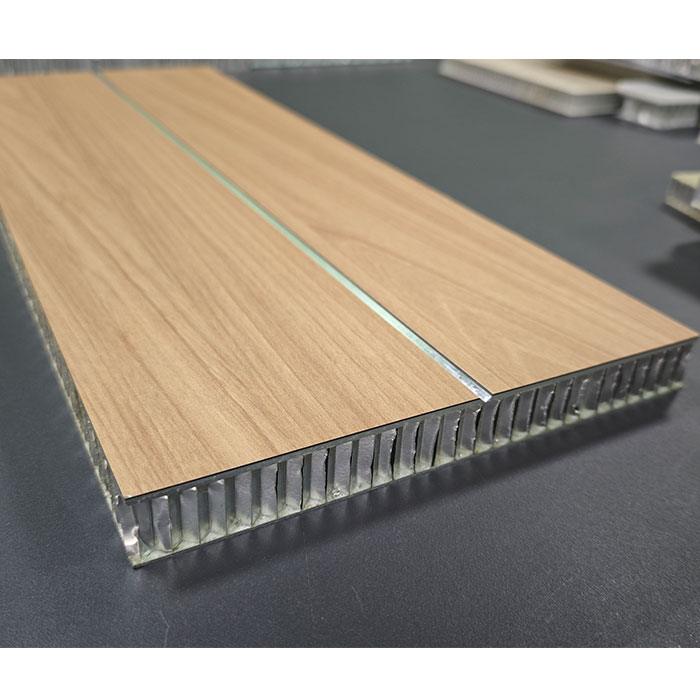

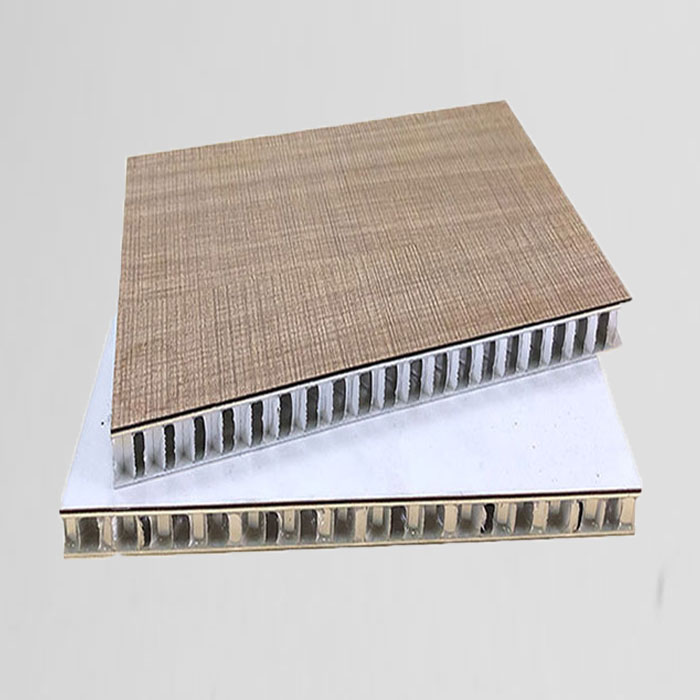

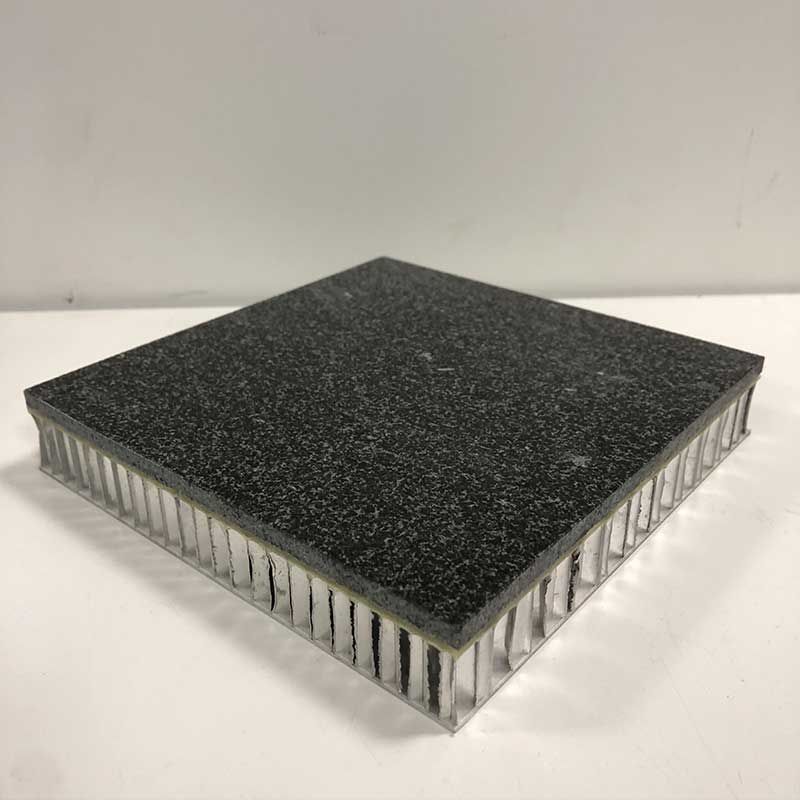

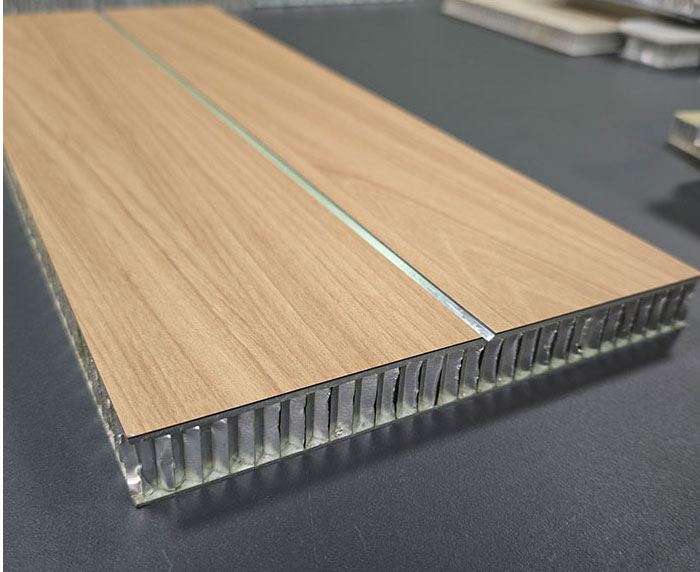

Honeycomb panel for rvs and marine table top

In the industry of recreational vehicles (RVs) and marine vessels, it is paramount important to enhance the functionality and aesthetics of table top material. And now, honeycomb panels are becoming the perferred material for rvs and marine as their unique structural advantages and excellent performance.

Characteristics of honeycomb panel tabletop

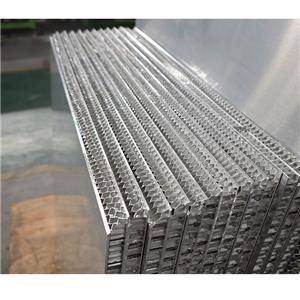

Lightweight and high strength

As honeycomb core structure, while maintaining high strength, the weight is more than 50% lighter than solid wood or metal tabletops, which is particularly suitable for vehicles with strict requirements for lightweight.

| Material | solid wood tabletop | honeycomb panel tabletop |

| Weight | 28 kg/m² | 12 kg/m² |

| Benefits | For every 100kg weight reduction, the fuel consumption of a motorhome can be reduced by about 0.3L/100km | |

Environmental protection and enhance value

Honeycomb panels are highly recyclable and meet green environmental protection requirements. High-quality table tops can enhance the overall grade and market competitiveness of RVs or marine.

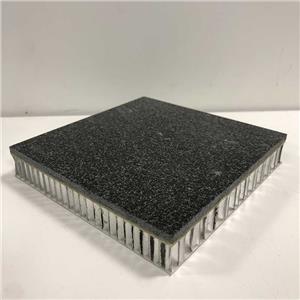

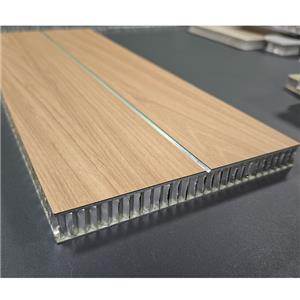

Aesthetics and customization

Honeycomb tabletop have multiple finish options,like matte, glossy, stone grain, metal texture etc. perfectly matching the style of RV or yachts. In addition, aluminum honeycomb can adapt to special design requirements such as curved countertop and folding tables.

Application

Aluminum honeycomb panels are used for rvs and marine tabletop. There are some cases as follow:

Yacht and passenger ship: used for operation consoles, bar counters, kitchen countertops, etc.

The kitchen countertop of a certain brand of yacht is made of aluminum honeycomb panel, covered with anti slip and wear-resistant coating on the surface, and integrated with a drainage system inside, which is both beautiful and practical.

Workboats and warships: In scenarios such as bridge operation consoles and equipment control consoles, their impact resistance and electromagnetic shielding performance (optional) meet the requirements of harsh environments.

The operating platform of a certain scientific research vessel adopts an aluminum honeycomb panel composite structure, with anti slip patterns embedded on the surface and integrated shock absorption modules at the bottom to adapt to extreme sea conditions.

Motorhomes and commercial vehicles: As kitchen countertops or workbenches.

The kitchen countertop of a certain brand RV adopts an aluminum honeycomb panel+quartz stone composite structure, which reduces the weight by 40% compared to traditional quartz stone countertops, while maintaining high hardness and high temperature resistance.

Special vehicles, such as fire trucks, medical vehicles, etc

The equipment table of a certain model of ambulance is made of antibacterial coated aluminum honeycomb board, which is easy to disinfect and impact resistant, meeting the needs of medical scenarios.