Aluminum Foam material for New Energy Vehicle

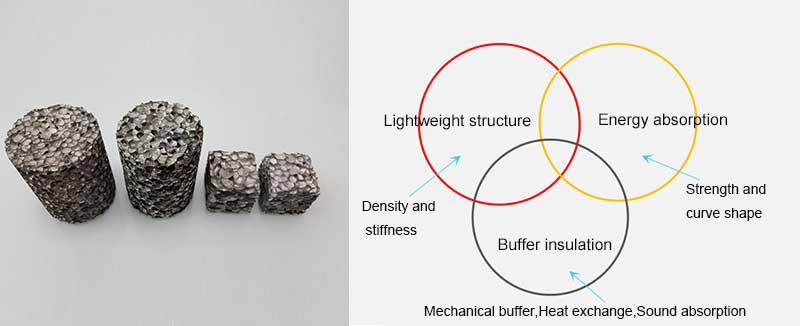

● Aluminum foam is a new type of multifunctional material with unique structure and excellent performance.

● lightweight structures, energy absorption and buffer insulation features

● to meet the lightweight and low-energy requirements of automotive design.

Description

Aluminum foam is a new type of multifunctional material with unique structure and excellent performance. The application of aluminum foam in the automotive industry mainly includes lightweight structures, energy absorption and buffer insulation,which to meet the lightweight and low-energy requirements of automotive design.

Lightweight structure

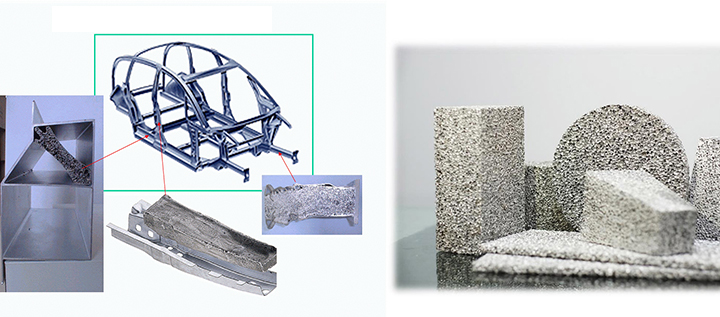

Foamed aluminum has low density and high specific stiffness. Auto parts made of foamed aluminum can not only meet the corresponding rigidity requirements, but also greatly reduce the weight of the car. If used with the metal foam, the weight of parts can be reduced by at least 1/3.About 20% of automobile components can be made of foam metal. Specific examples of auto parts that can be made:

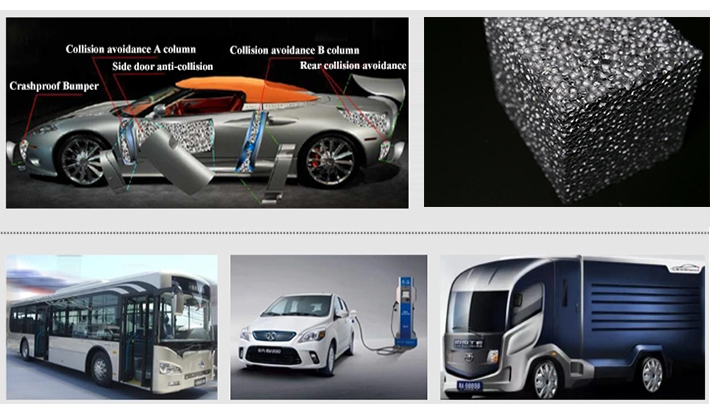

Front, rear and side bumpers and fenders of cars

Door trims, roof trims and engine compartments of car

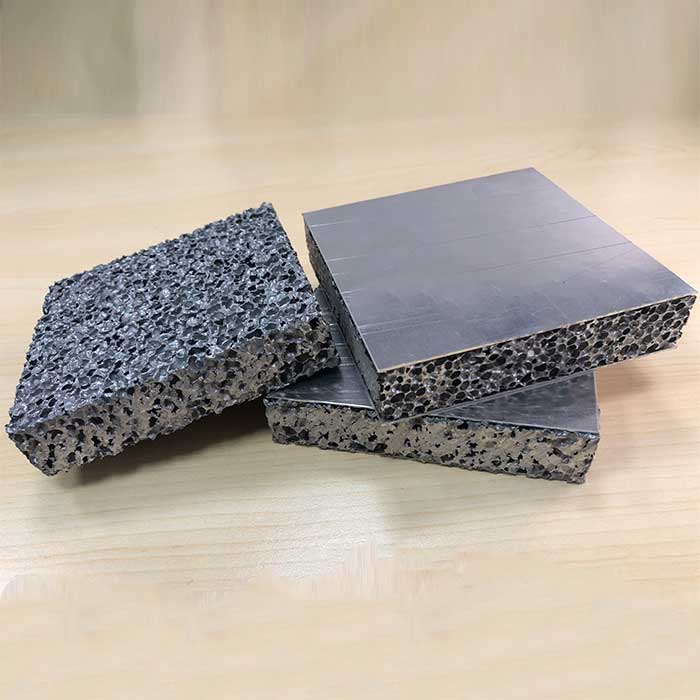

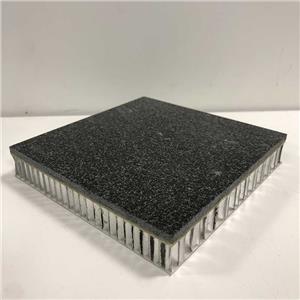

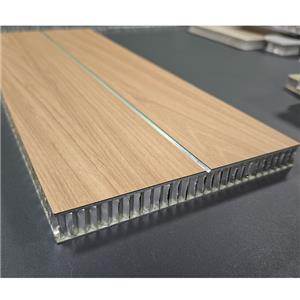

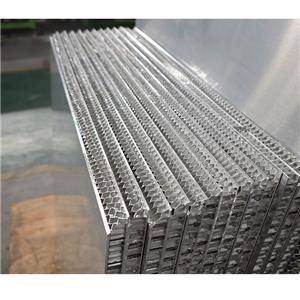

The application of foamed aluminum in automobile manufacturing is mostly foamed aluminum sandwich structure. The foamed aluminum sandwich structure includes foamed aluminum shaped parts and foamed aluminum sandwich panels. The core layer of the aluminum foam sandwich structure is aluminum foam, and the inner and outer cladding layers are aluminum plates or other metal sheets.

Buffer insulation

aluminum foam can be divided to open cell aluminum foam structure and closed cell aluminum foam structure.

The application of open cell aluminum foam can be sound absorbers, heat exchangers and filter because it offers various properties such as thermal conductivity, electrical conductivity, high porosity, and corrosion resistance.

Aluminum foam is primarily used as anti-intrusion bars in electric automotive. Properties like good kinetic energy absorber and lightweight of this technology along with cost effectiveness have contributed to its intensive usage for developing crash guards in automotive industry.

Energy absorption

The porous structure of the aluminium foam absorbs the impact energy. This property can be used during transport to protect against collisions, as armor and explosion protection.

Physical characteristics

Type | Available in closed-cell, open-cell ,micro-open-cell |

Form | foam panel,or sandwich foam panel |

Pore diameter | 3-8mm |

Size & Shape | can be made in different shape as per request |

Density | 0.2-0.6g/cm 3 |

Size availability | 520*520,1000*2000,1200*600 |

Acoustic absorption coefficient NRC | 0.7 |

Fire-proof level | A1 |

Sound absorption (1000Hz -2000Hz) | 40% ~ 80% |

Compressive strength | 3-10Mpa |

Specific stiffness | 1Gpa/gcm 3 |